MCR-2E

- • Zero Added CO2 all ELECTRIC Heat

- • 2 KILOGRAM (4.4 POUND) BATCH CAPACITY

- • AUTOMATION READY

- • DIGITAL ROASTING SYSTEM

- • OPERATOR-ASSIST SENSOR PACKAGE

- • CSA® DESIGN CERTIFIED

- • Optional Factory NSF Certification

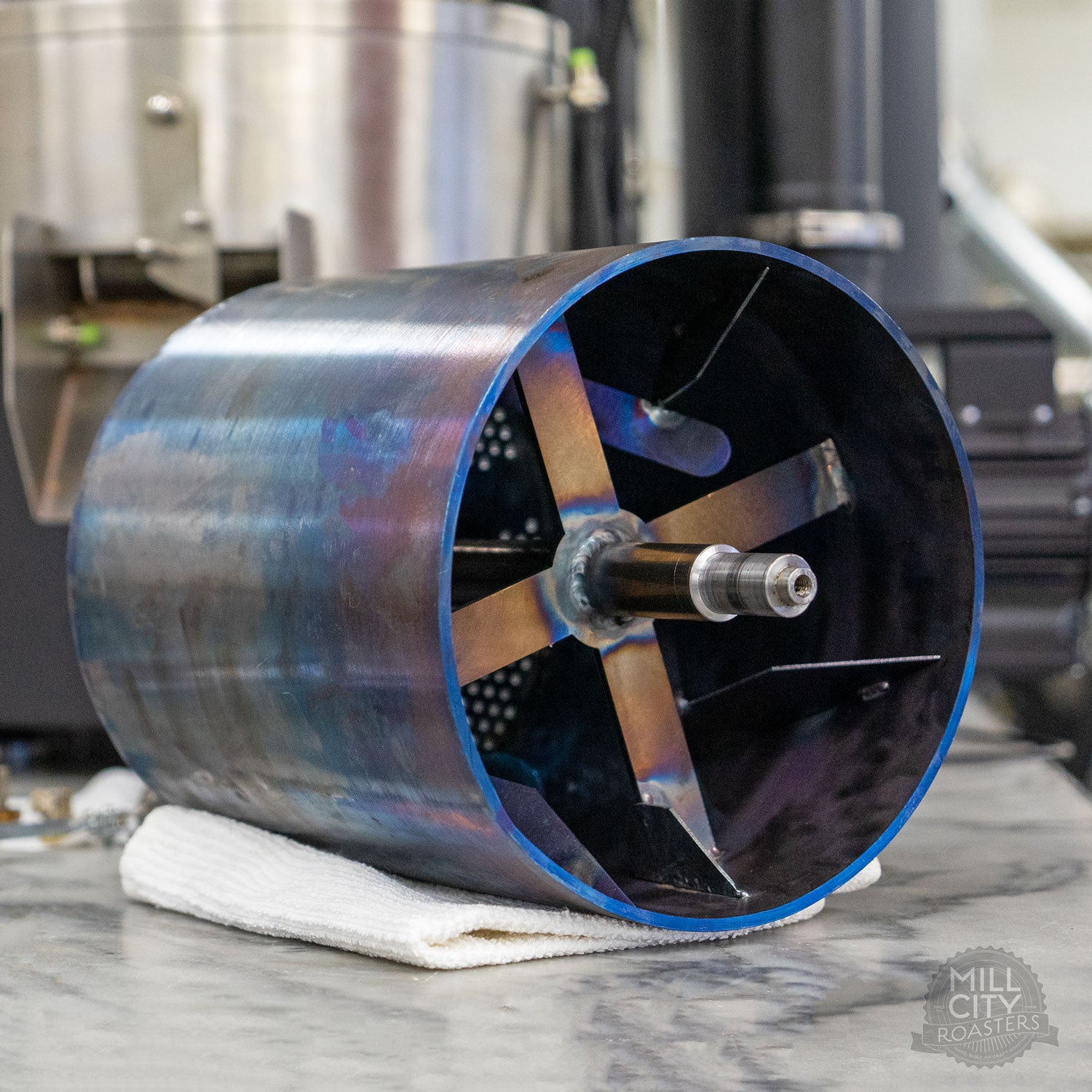

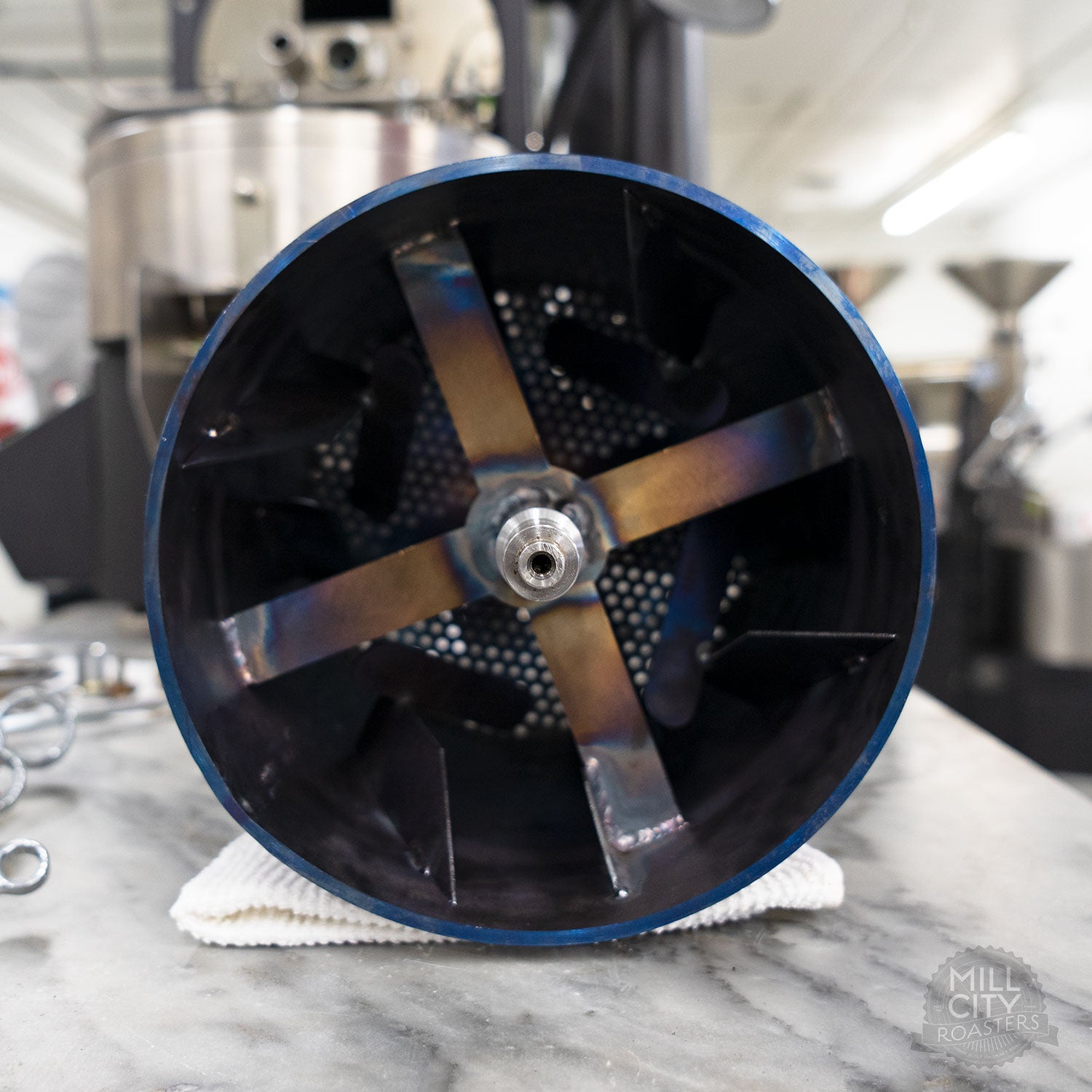

- • Custom Made-in-Minneapolis Ferrous Steel Drum

- • CREATES $338+/HOUR

2 Kilogram Coffee Roaster, MCR-2E

New for 2024 - our new electric coffee roaster!

The new MCR-2E roaster is the industry’s first zero-added carbon emission studio and lab roaster designed for precision small batch production and roast performance.

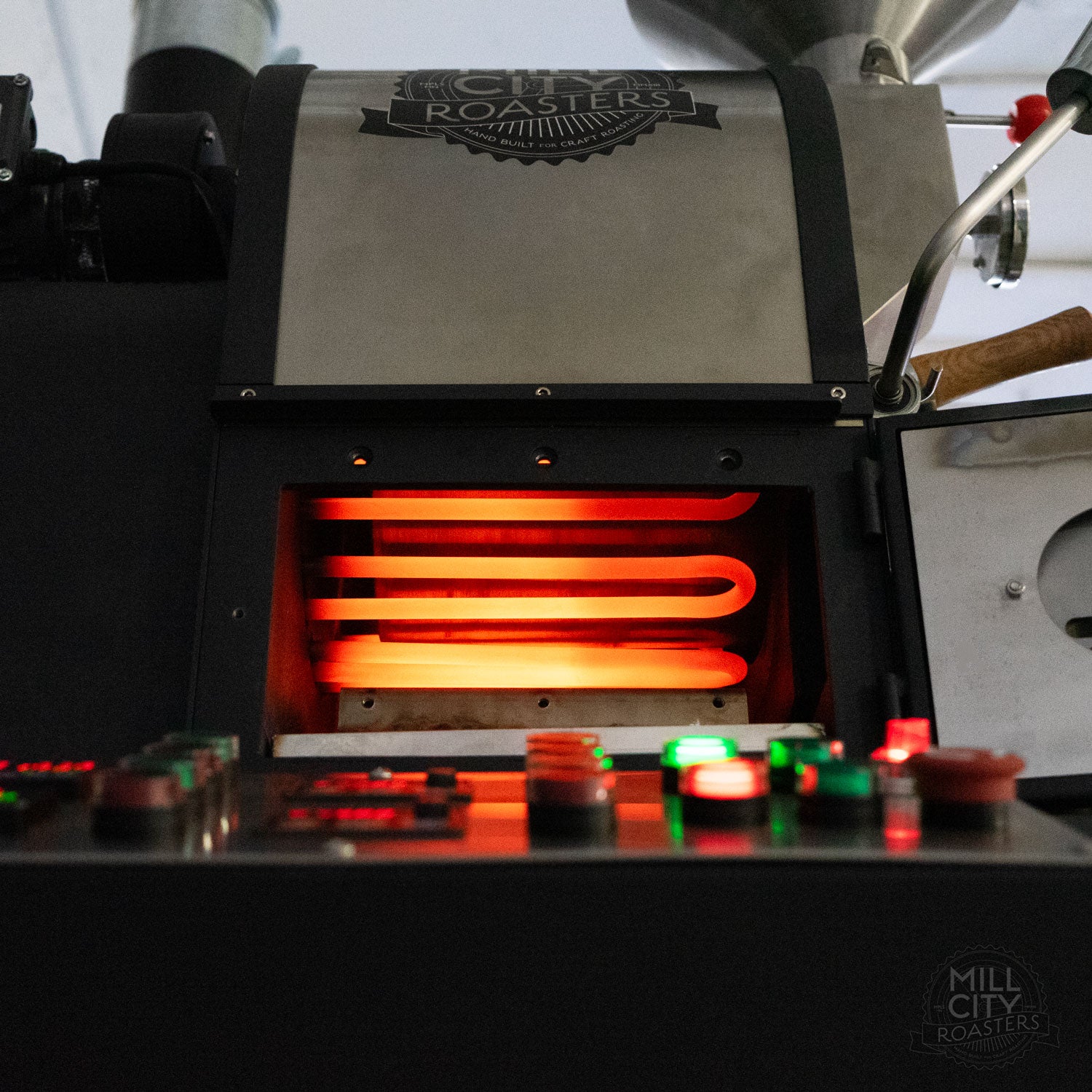

Each MCR-2E features a custom-designed, single-walled, ferrous steel drum made in-house at our Minneapolis manufacturing facility. This drum design optimizes heat transfer from the custom, US-made, 5000 watt heating elements while eliminating the charred chaff roast flavor and uneven roasts associated with thin walled stainless perforated drum designs attempting to boost performance by allowing infrared impingement on the seed.

Heat output on the MCR-2E is provided by a highly sophisticated, programmable square wave controller. This system reduces latency induced response lag and set-point overshoot. It also provides digital connectivity, increases heating element life, and overall system longevity and reliability.

The remainder of the all-digital control system integrates seamlessly with RoastPATH®, including the highly requested Roast Replay feature. During the roast, RoastPATH® automatically logs BT, ET, IT and DT temperature readings, initial charge state settings, and fan, fuel, and drum speed adjustments. Direct drum pressure is also logged as a feedback loop for operator controlled and automated roast airflow changes.

This model includes the Operator Assist System which automatically recovers to production charge temperature settings, starts timers, and triggers the cooling tray fan and stirring arms off/on at discharge from the drum or cooling tray. This system also incorporates position sensors that make it nearly impossible to accidentally discharge green coffee from the drum into a cooling tray filled with roasted coffee.

The MCR-2E is optionally available with UL® Sanitation certification necessary to meet NSF requirements for installation in retail food service locations in California.

- Choose from three optional layouts using our Quick-Connect kits to arrange components and exhuast -or- request a custom layout

- Optional UL® NSF (National Food Safety) package.

- Optional zero-emmision electrically heated Reicatio 100 scent elimination

Next available: 2 in-stock in Minneapolis!

Arrives in one crate

Roaster crate: 55″ x 44″ x 59″, 650 pounds

Request a quote to see costs to your location.

This equipment is covered by Mill City Roasters' warranty.

Photo by Relative Coffee Co in Minneapolis, MN

PRODUCTIVE CAPACITY

THE MCR-2E CREATES $338 PER HOUR

Roasting 4 full batches an hour on an MCR-2E creates over 14 pounds of roasted coffee every hour. This yield is enough roasted coffee to fill more than 18 12-ounce bags. With a retail value of $18 per 12-ounce bag, you can create $338 of retail coffee per hour.

Want to see how your business expenses stack up against that income? Use our Roaster Income Calculator to use your real-life expenses and find a roaster capacity that works for your business plan.

Features

Chassis

- Monolithic, low carbon steel weldment – the heaviest constructed roasters in their class.

- Fully gusseted for dimensional strength and stability.

- Fully coated to prevent corrosion.

- Integrated double-walled roast compartment is heavily insulated which further converts the chassis into a thermal battery – storing heat, rather than wasting it.

- Materials in both the chassis and the roast compartment absorb heat more efficiently and release heat more consistently for increased stability of temperatures during profiling.

- Trapping heat = trapping noise. Ambient drum noise is limited to a whisper quiet 60 decibels making it easier to hear those early outliers before first crack.

Drum

- Made-in-Minneapolis ferrous steel drums standard on every model.

- Single walled drum passes greater conductive heat for better performance with electric heating elements.

- Solid drum wall eliminates burning chaff roast defect flavors common to most electriclly heated roasters.

- Construction accuracy is machine trued to within +/- .015”.

- Heavy integrated precision laser cut construction prevents warping due to operator error.

- Every model equipped with quick response, variable drum speed allowing the operator to achieve ideal bean loft and conductive vs. convective ratio. Result is the flexibility to profile batches from 20%-100% of listed drum capacity.

- Advanced drum gap adjustment mechanism is standard on all models two kilogram capacity or greater, making adjustments easier and more precise.

Heating

- Custom-designed, US Made UL listed heavy duty heating elements.

- Built-in temperature limiters to allow for safe operation.

- Digital electronic programmable square wave modulation of heat output provides precision roast control.

- Push button heat control.

- Automated roast profiing via RoastPATH Automation connectivity.

Air & Exhaust

- Power-vented dual exhaust system standard on every model with fan placement designed to allow for easy cleaning and maintenance.

- Roaster exhaust fan is high pressure, high output 3-phase VFD speed controlled with linear response curve for more predictable and more precise airflow control and roast profiles repeatability.

- Cooling tray exhaust fan is a dedicated, high-pressure fan providing rapid cooling to stop roast progression once batch is dropped in cooling tray. Dual exhaust system allow for simultaneous roasting and cooling, reducing back-to-back batch times and increasing production to 4+ batches per hour.

- All machines include face-mounted digital drum pressure gauge.

- All models equipped with dedicated, off-board chaff filtering collectors with easy access doors to aid in frequent clearing of chaff and completion of safety checks.

- Optional quick-release venting kits available for every model.

- Fully specified requirements for venting to termination including layout and cap recommendations.

- Fan adjustments at the push of a button.

Safety

- CSA® Certified C22.2 No. 109-17 and UL197 for US and Canada, IEC, CE, ROHS.

- All UL/CSA certified Delta PLCs and VFDs.

- CSA/UL certified motors, relays, switches, and wiring.

- Optional UL® NSF Certification available on every model.

- Food contact path including hopper, loading chute, faceplate, trier, discharge gate, discharge chute, cooling tray cover, cooling tray floor, stirring/mixing arms, cooling tray gate, cooling tray latch, cooling tray gate) all custom fabricated with certified food grade stainless. Drum is food safe US made ferrous steel.

- Teflon cooling tray wipers.

- Heavy duty 5mm x 44mm Borosilicate sight glass.

- Food service safe LED light.

- Food safe resin-impregnated trier handle.

- Stirring arms automatically stop when the cooling tray cover is opened.

Install & Maintain

- Designed for benchtop installation.

- Detachable chaff collector and cooling tray fan for moving components through standard size door openings. Removable hoppers on all models.

- Quick-Connect Kits available to arrange exhaust for routing to termination outdoors.

- Removable access doors on both sides for easy access to interior components.

- Warranty

Planning & Installation

Electricity

Requires a dedicated single phase circuit, 230V, 23A, 60 Hz.

Unit arrives with a power cord measuring 3 feet (1 meters) terminated with a NEMA L6-30 plug.

Venting

Requires dedicated Category III, Positive Pressure exhaust line(s) to carry exhaust from roaster drum & cooling tray to termination outdoors.

See installation manual for maximum runs, minimum heat ratings and clearance-to-combustible requirements. Our Design Team offers free consult to help you make a plan for your building.

Take a closer look

from our video library

MCR-2E electric roaster rundown

Lauren gives us a tour of our new all-electric two kilogram coffee roaster.