MCR500

- • 500 GRAM (1.1 POUND) BATCH CAPACITY

- • CSA® DESIGN CERTIFIED

- • HEAVY COMMERCIAL BUILD

Photo by Koyanagi Coffee in Shimogarako, Saitama, Japan

500 Gram Sample Roaster, MCR500

The Mill City Roasters® 500 gram sample roaster is designed for highly efficient green coffee sample roasts as well as exploratory small-batch profile design as a starting point for production roast profile planning.

The MCR500 is a professional commercial coffee roaster with the same plate steel weldment construction and double-walled drums as our larger and more expensive models.

This model is RoastPATH® connectable with an integrated USB port that passes BT, ET, and DT thermocouple readings along with input changes in fan speed and resultant digital drum pressure. The roaster is equipped with variable drum speed for optimal roasting from batch sizes from 100 to 600 grams. Control on this machine is via hand adjustments of the gas input and power input for the fan and drum speed.

The 500g is available in an NSF certified configuration.

- Roaster with integrated cooling tray & chaff collector

- Thermocouples measuring BT, ET, and DT

- Digital drum pressure gauge

- Pre-delivery support from our design team including space planning review, venting specification & project advice

- Set-up call: 1-on-1 video call with our Support Team to review your installation before passing you on to a 1-on-1 video call with our Roastery Team to complete your first seasoning roast

- Warranty

- Choose from three optional layouts using our Quick-Connect kits to arrange components and exhuast -or- request a custom layout

- Optional UL® NSF (National Food Safety) package.

Next available: Call for availability.

Arrives in one crate

Roaster crate: 42″ x 24″ x 38″, 252 pounds

Request a quote to see costs to your location.

This equipment is covered by Mill City Roasters' warranty.

Professional Greens Sampling

Learn about our in-house sample roasting protocol and five mistakes to avoid in your sampling practice. If you’re roasting a lot of samples, which we occasionally are, and you want to minimize variance in the roast, it’s best to find a set of roaster inputs that can remain static. This means that you won’t have to make any adjustments during the roasting process, so it’s less likely you’ll miss a fuel or an air change. We worked to find the settings which would allow us to reach our target roast color in the recommended amount of time.

Features

Chassis

- Monolithic, low carbon steel weldment – the heaviest constructed roasters in their class.

- Fully gusseted for dimensional strength and stability.

- Fully coated to prevent corrosion.

- Integrated double-walled roast compartment is heavily insulated which further converts the chassis into a thermal battery – storing heat, rather than wasting it.

- Materials in both the chassis and the roast compartment absorb heat more efficiently and release heat more consistently for increased stability of temperatures during profiling.

- Trapping heat = trapping noise. Ambient drum noise is limited to a whisper quiet 60 decibels making it easier to hear those early outliers before first crack.

Drum

- Double-wall, stainless steel drums standard on every model. The heaviest, most-efficient drum design in the industry.

- Construction accuracy is machine trued to within +/- .025”.

- 3mm air gap between inner and outer drum diffuses heat more evenly throughout inner drum.

- Diffused heat at inner wall eliminates conductive roast defect, even at higher inlet temperatures.

- Dramatically increased thermal efficiency by storing & using heat, rather than quickly releasing.

- “Bomb proof” construction prevents warping due to operator error.

- Every model equipped with quick response, variable drum speed allowing the operator to achieve ideal bean loft and conductive vs. convective ratio. Result is the flexibility to profile batches from 20%-120% of listed drum capacity on most models.

- Advanced drum gap adjustment mechanism is standard on all models two kilogram capacity or greater, making adjustments easier and more precise.

Fuel

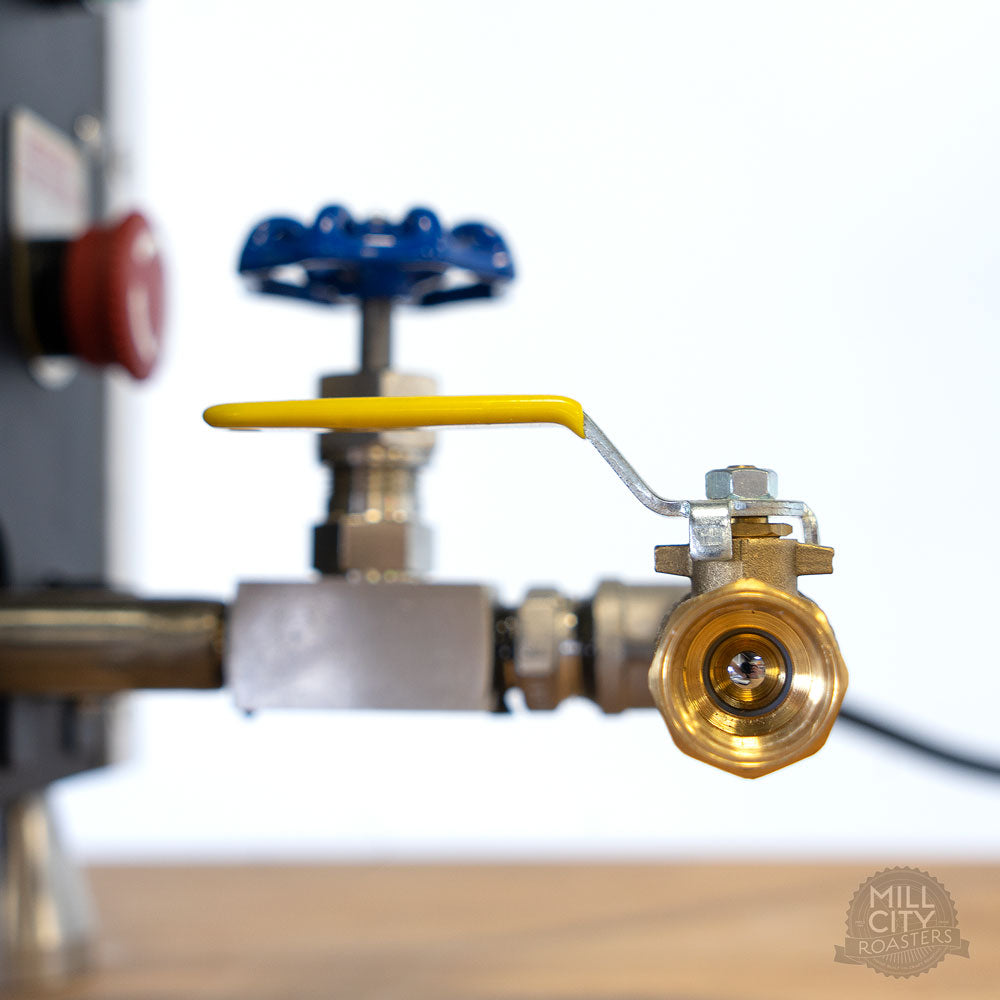

- Custom-designed, CSA® Design Certified low loss gas train designed by Mill City Roasters and used exclusively in our roaster line-up.

- Custom burners designed specifically for coffee roasting.

- Burner layout is specific to each model to achieve optimal burner-to-drum relationship.

- Easy access, external shut-off valves on every roaster.

- Built-in temperature limiters to allow for safe operation.

- Built-in safety shut-off on pilot valve.

- Easy on-site conversion from LP to natural gas.

- High precision CV needle valves.

- Precision analog gas gauge.

Air & Exhaust

- Power-vented dual exhaust system standard on every model with fan placement designed to allow for easy cleaning and maintenance.

- Roaster exhaust fan is high pressure, high output 3-phase VFD speed controlled with linear response curve for more predictable and more precise airflow control and roast profiles repeatability.

- Cooling tray exhaust fan is a dedicated, high-pressure fan providing rapid cooling to stop roast progression once batch is dropped in cooling tray. Dual exhaust system allow for simultaneous roasting and cooling, reducing back-to-back batch times and increasing production to 4+ batches per hour.

- All machines include face-mounted digital drum pressure gauge.

- All models equipped with dedicated, off-board chaff filtering collectors with easy access doors to aid in frequent clearing of chaff and completion of safety checks.

- Optional quick-release venting kits available for every model.

- Fully specified requirements for venting to termination including layout and cap recommendations.

Safety

- CSA® Design Certified CSA 1.8 for US and Canada, IEC, CE, ROHS.

- CSA/UL certified Honeywell automatic ignition controller

- All UL/CSA certified Delta PLCs and VFDs.

- CSA/UL certified motors, relays, switches, and wiring.

- Optional UL® NSF Certification available on every model.

- Entire contact path of roaster (hopper, loading chute, faceplate, trier, drum, discharge gate, discharge chute, cooling tray cover, cooling tray floor, stirring/mixing arms, cooling tray gate, cooling tray latch, cooling tray gate) all custom fabricated with certified food grade stainless.

- Teflon cooling tray wipers.

- Heavy duty 5mm x 44mm Borosilicate sight glass.

- Food service safe LED light.

- Food safe resin-impregnated trier handle.

Install & Maintain

- Integrated chaff collector.

- Removable hoppers on all models.

- Quick-Connect Kits available to quickly connect components and arrange exhaust for routing to termination outdoors.

- Warranty

Planning & Installation

Gas

Operates on LP gas or natural gas. Requires commercial gas pressure via 1/2" NPT connection. See installation manual for detailed pressure requirements.

Burners arrive configured for LP gas but can be converted for natural gas using our easy, on-site conversion kit.

We can also help sourcing the correct gas regulator for your installation and talk your installer through any questions they have regarding gas pressure.

Electricity

Requires a dedicated single phase circuit, 220-230V, 15A, 50-60Hz.

Unit arrives with a power cord measuring 3 feet (1 meters) terminated with a NEMA 6-15 plug.

Venting

Requires dedicated Category III, Positive Pressure exhaust line(s) to carry exhaust from roaster drum & cooling tray to termination outdoors.

See installation manual for maximum runs, minimum heat ratings and clearance-to-combustible requirements. Our Design Team offers free consult to help you make a plan for your building.

TAke a closer look